Cable ability

Conductor

Made of metal to transmit current、electromagnetic wave and data. Or use fiber for optical communication network.

Choose the conductor material base on: Conductivity / Flexibility / Solderability / Temperature / Cost…etc

Conductor – Materials

Bare copper / Tin-plate copper / Silver-plate copper / Nickel-plate copper / Gold-plate copper / Copper-Clad Steel / Aluminum / Steel / Tinsel Wire / Fiber

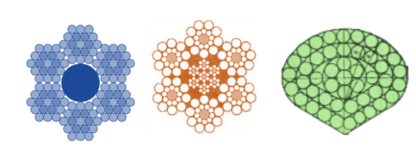

Conductor - Conductor construction

Solid / Stranded (Concentric / Bunched / Special bunched)

Insulation

Wrapped around the conductor and insulated the electrical role, ensure the transmitted current or electromagnetic wave and light wave also the safety of external objects.

Insulation – Materials

HDPE / MDPE / LDPE / LLDPE / PEF (Foam PE) / PP / PVC / FEP / PFA / ETFE

Assembly (Cabling)

Assembling two or more materials like insulated conductors、twisted pairs、filler、shielding material、ground conductor... twist together, to become one assembled cable

As the sample of assembly construction as below, the combination has diverse style and it is hard to be defined.Due to this reason, please feel free to contact us for your customized requirement.

Filler

Base on the filled material to meet the different applications.

For lessening the effects of EMI、increase the strength function、flexibility or the shape of the cable...

Filler – Application

Water Proof / Tensile strength / Softness / Roundness & OD control

Filler – Materials

GEL / Aramid yarns / Cotton paper / Yarn rope / PE

Shielding

Electromagnetic isolation to prevent the information transmitted leak out from the cable also prevent external instruments or other lines various external electromagnetic. Reduce Interference / Increase Flex Life / Act as a Barrier

- Shielding method and structure can be multiple varied, based on the use environment to choose different shielding

- More layers of shielding, the better the ability to prevent noise from entering or emitting

- To prevent noise between assembly pairs

- Braiding - EMI resistant, better with low frequency application

- Spiral: Same softness as braided, with better bending ability

- Tapes & Wraps - anti-static interference, better with high frequency application

Shielding – method

Braiding / Spiral / Tapes & Wraps

Jacket

For different application demands and protection against environmental factors like resistance of mechanical forces, environment resistance, chemical resistance or oil resistance, prevention of biological damage, and reduction of fire hazards. It is a crucial part of the cable and can be the determining factor for the longevity and durability of the cable or cable assembly.

Jacket – Materials

LDPE / PVC / PP / LSZH / HT (HYTREL) / TPU(PUR) / TPEE / TPO / TPE / TPV / ETFE / FEP / PFA

Jacket – Shape(inside/outside)

Round / Zigzagged / Flat / Dual

256 bit SSL Encryption

256 bit SSL Encryption