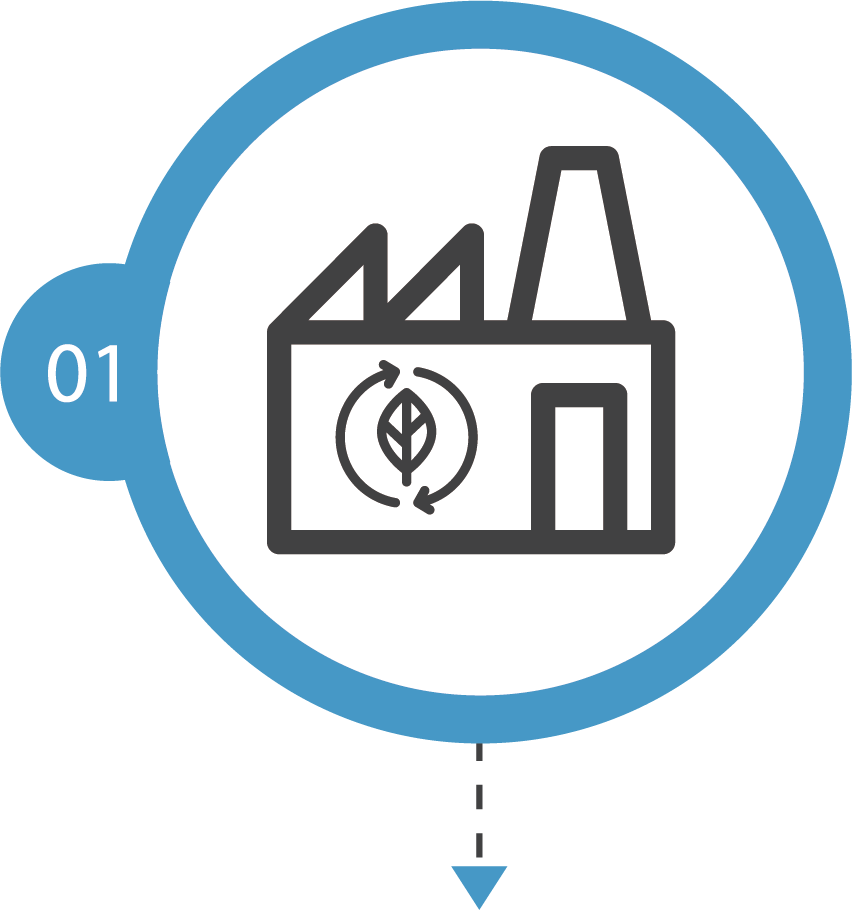

CTi will soon open a new China plant in Q3 2023.

We are thrilled to announce the construction project of CTi’s new plant in Dongguan, China and it will be completed soon in 2023. Upon completion, our cable assembly factory (JCE) will be relocated to the new plant.

With the long-term vision of sustainable manufacturing, CTi Group is taking steps to implement green practices to increase our energy efficiency and conservation. Constructing new manufacturing facility has always been considered as an integral part of our ESG (environmental, social, and corporate governance) goals. In addition, CTi continues to improve production efficiency through rescheduling the production line, implementing management tools, upgrading equipment and setting up new production line.

With a 60-year history in the cable manufacturing and assembly business, CTi Group has achieved the leading position in the industry through our values and business philosophy based on a trinity of key differentiating strengths: sustainability, excellence, and value creation. The new plant will bring new technologies, new production line, and additional automation so that we can continue to innovate to provide diverse custom cable solutions and excellent customer service adhering to our stringent quality policy.

Key Highlights

ESG and Green Factory

- Ice storage air conditioning system

- Replace the traditional air conditioning system with ice storage air conditioning system to reduce energy consumption and greenhouse gas emissions.

- Reducing solar heat gain in the building

- Install Low-E (Low Emissivity) glass windows, insulate the roof with multi-layer thermal insulation materials and build thickened brick walls on the west side of the building to minimize heat gain from the sun and to keep cool air from escaping.

- Separated sewage systems for rainwater and wastewater

- Establish the individual sewage system to avoid discharging the untreated wastewater directly into the sewer.

- Implement water-saving equipment

- Use automatic flush toilets and other water-saving devices to reduce water consumption.

ISO and CSR

- ISO13485

- Medical devices quality management systems standards

- ISO16949

- Automotive quality management systems standards

- BSCI

- The amfori Business Social Compliance Initiative (BSCI)

e-Factory

- Manufacturing Execution Systems (MES)

- Enable access to production traceability with barcode traceability system.

- Overall Equipment Effectiveness (OEE)

- Our test equipment is connected to the network and the test data is uploaded to the server automatically.

- Visual management

- Implement digital signage to display SOP and real-time production reporting to achieve visual management.

High-efficiency workshop

- Component workshop

- Redesign the piping and group together the equipment or department that perform similar tasks such as injection molding machine, die casting machine and tool room for improvement of production efficiency.

- Finished-product assembly workshop

- Reschedule the assembly line to ensure a smoother flow and greater production efficiency.

- Continue to increase the level of automation manufacturing.

SMT Line

- Build our own SMT line for in-house production of PCBA to strengthen CTi’s vertically-integrated manufacturing capabilities of electrical products.

CTi Group is a professional cable OEM/ODM solution provider established in Taiwan for over 50 years. CTi Group has been dedicated to the integrity of high-frequency and high-speed cable industry for many years which provides customers with product design, development, and production solution by integrating outstanding tooling design, industrial automation, and procedure capability. CTi Group’s main products include HDMI, USB, DP, networking cable, VR HD cable, automotive cable, industrial and medical cable, etc.

256 bit SSL Encryption

256 bit SSL Encryption